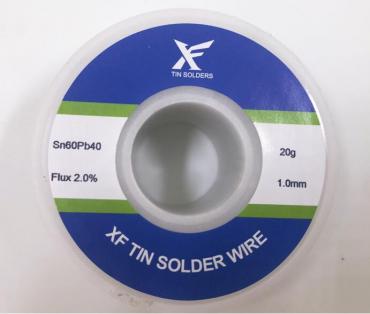

| Name: | 60/40 electrical solder |

| Name: | 60/40 electrical solder |

| Alloy: | Tin Lead |

| Composition: | 60/40 |

| Form: | solder wire & solder bar |

| Origin: | China |

Product Description

60/40 electrical solder

What is 60/40 electrical solder?

60/40 electrical solder is a very typical solder among the solder family. 60/40 indicates that this solder is a tin & lead alloy solder, with 60% by weight is tin, and the remaining 40% by weight is lead. And it's for electrical soldering purpose. This 60/40 electrical solder is available in two forms: one is 60/40 electical solder wire, the other one is 60/40 electrical solder bar.

What are the features of 60/40 electrical solder?

1. 60/40 electrical solder has a very small plastic range, melting point is 183 to 190℃. Easy to melt and easy to solid, good for electrical soldering. If you would like to ask if there is much difference between 60/40 solder and 63/37 solder, personally I would say not too much difference. And try google it you will find some people vote for 60/40 and some vote for 63/37.

2. Good electrical conductivity, as it contains high tin which makes the solder joint has good electrical conductivity.

3. If you're using our 60/40 electical solder wire, we make this solder wire with no clean rosin flux core and it's very handy to use. No matter for personal use for repairing or for electrical appliances factories, the 60/40 electrical solder made with a rosin core can help to increase the production efficiency, because there's no need to apply external flux in particular. Easy for most users. And the rosin flux core is neutral which are with very little, non aggressive residue that requires no cleaning after soldering.

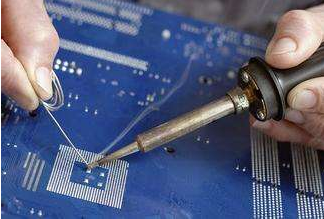

How to use the 60/40 electrical solder?

1. If you're using the 60/40 electrical solder wire, the type with rosin flux core ss more for manual soldering, and for automatic soldering robots generally a solid core wire would be used and then apply with external flux. Make sure that you don't get the wrong type of flux, if you use acid core solder wire for electrical soldering, you will have problem because the flux is too aggressive which could lead to corrosion of the solder joint after soldering.

2. 60/40 electrical solder bar will be applied by way of dip soldering or wave soldering. Both these two types of aplications greatly improve the soldering speed considering to do soldering with solder wire. As the 60/40 electrical solder bar will be melted inside the solder bath and then one THT or PCB can be soldered at one time.

Contact our sales team for more details of 60/40 electrical solder. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 008613450770997, main website www.xfsolder.com